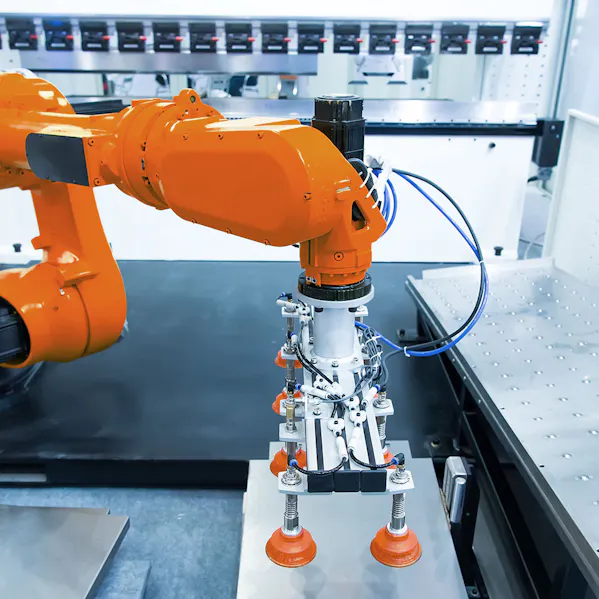

Automation with the Smart Factory

For many medium-sized companies, the upstream and downstream processes mapped in SAP ERP provide a valid basis for automation - all that is needed is an extension regarding machine data logging functionalities. This is exactly what the Smart Factory enables you to do: You can automate and digitize specific processes and integrate them into continuous end-to-end processes.

The flexible approach of the Smart Factory allows you to proceed step-by-step and start exactly where large optimization potentials can be quickly realized. In this way, you digitize your shop floor without having to struggle with the implementation of complex third-party systems (such as an MES).

The machine data loggins stages of the smart factory

The All for One Smart Factory enables you to drive automation and digitization on the shop floor step-by-step without a large initial investment.

Stage 1: Automation of processes

Stage 2: Starting production orders with the Smart Factory

Stage 3: Better Understanding your machines

Customized solutions and projects based on the smart factory

Beyond the standardized machine data logging stages, customized solutions and projects based on the Smart Factory are possible. This enables you to automate production processes to an even greater extent.

You want to learn more about All for One Smart Factory?